Grease Trap, Jumbo2

£331.00 Original price was: £331.00.£97.99Current price is: £97.99.

- Shop the Best Quality Online

- Buy quality, buy with us.

- High quality products, low prices.

- There are quality problems, free return and exchange

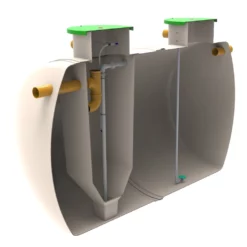

Jumbo 2 Grease Trap

Internal Baffle and dip pipes that trap fats, oils and grease through natural separation prior to entering the mains sewage system. Ideally suited for small to medium kitchens, restaurants and catering facilities. The use of a grease trap or separator should be a prerequisite for any architect, consultant or contractor who is designing or developing property that will have catering or food processing facilities.

Grease traps have been used predominantly in the catering industry to prevent a build up of grease and liquefied fats from solidifying and blocking the flow to the drainage system. The installation of a grease trap is particularly important in kitchens where more than 30 meals per day are to be served regularly and in food processing plants and abattoirs, where animal fats and bi products are discharged into the foul drainage system.

These days a grease treatment system should be specified and installed as an integral part of the drainage design on restaurants, catering establishments and process plants and abattoirs, particularly those connected to a packaged sewage treatment systems. The specification of the correct grease treatment system is imperative in supporting the drainage system and the sustainability and performance of the final treatment process.

The Jumbo design reflects 20 years of industry experience and product design, and we are delighted to offer this unique product to the market. Manufactured from HDPE, it is extremely lightweight at 20 kilos, however also very durable with a 50-year design life. Its unique circular baffle sets it apart from other traps on the market, and the name Jumbo comes from its profile, which we think looks like a small elephant.

How they work:

Wastewater containing oils and grease enters the Jumbo where light liquids i.e. Oils, grease and liquefied fats gravitationally settle out at the top of the primary chamber and the heavier material i.e. vegetable matter and fines drop to the base of this chamber. Heavily emulsified greases, fats and oils that are not completely separated will again drop to the base. Cleaner separated water is then channelled across into the second chamber under the circular baffle, this is probably the Jumbo’s main design feature and the

location of this baffle is critical as the baffle stops oils and greases from migrating across the top of the grease trap and when the suspended oil level reaches the bottom of the baffle, it flows around the baffle face and is then retained at the top of the second chamber. This gives a much greater storage/retention for cooking oils and liquefied fats. The baffle also adds to the strength of the unit as it runs right through the unit. The second chamber has a dip pipe attached to the outlet which allows for a substantial build up of suspended oils and greases in both chambers and its location allows for cleaner separated water to discharge.

What can enter the separator ?

Only wastewater containing organic greases and oils, which are required to be separated from the water, should be allowed into the trap. Under no circumstances should sewage, rainwater or wastewater containing mineral oils (hydrocarbon based) be allowed to enter the separator. Catering traps are sometimes known as grease traps.

Delivery

All our Grease Traps are for delivery by customer offload. This entails the customer to acquire the right manpower and/or machinery to help unload the tank/s from the delivery vehicle.

If you require assistance with offloading, we may be able to offer a tail lift (lowers the tank to the ground) or HIAB (lorry with a mounted crane to winch the tank off the delivery vehicle). Please contact us if this is required for delivery.

Product Details

- Product Code: OE

- Colour: Black

- Customer Offloading: Customer Offloading

- Material: HDPE (High density polyethylene)

- Tank Use: Below Ground

Be the first to review “Grease Trap, Jumbo2” Cancel reply

Related products

Separators, Silt Traps, Washdown Separators

Klargester Sewage Treatment Plants

Klargester BioAir 6 Gravity Sewage Treatment Plant – 20 Person

1 - 9 Person Sewage Treatment Plants

Harlequin Sewage Treatment Plants

Harlequin Sewage Treatment Plants

Above Ground Sewage Pump Stations

Above Ground Sewage Pump Stations

Reviews

There are no reviews yet.